2026 Best Aviation Fuel Systems How Do They Work?

The aviation fuel systems industry plays a crucial role in ensuring the safety and efficiency of air travel. According to a recent report by MarketsandMarkets, the global aviation fuel systems market is projected to reach $XX billion by 2026, highlighting significant growth. These systems are not merely about storing and delivering fuel; they involve complex engineering and technology. Peter Johnson, an aviation fuel systems expert, emphasizes, "Understanding how these systems function is vital for optimizing performance and safety."

Aviation fuel systems must adapt to the increasing demands of greener technologies while maintaining high safety standards. As the industry progresses, manufacturers focus more on innovation. The integration of advanced materials and electronic controls can enhance efficiency but introduces new challenges. For example, the transition to sustainable aviation fuels requires a thorough understanding of current systems and their limitations.

The quest for performance does not come without risks. Minor failures in fuel systems can lead to severe in-flight emergencies. While improvements are evident, experts often reflect on the necessity of rigorous testing and quality assurance. Continuous education and awareness are key to addressing the evolving complexities of aviation fuel systems.

Overview of Aviation Fuel Systems: Definition and Importance

Aviation fuel systems are essential for the safe operation of aircraft. They are designed to store and deliver fuel to the engines efficiently. According to a report by the International Air Transport Association, nearly 80% of aircraft incidents related to fuel are linked to system failures. This emphasizes the importance of having reliable fuel systems in aviation.

These systems function by utilizing various components such as fuel tanks, pumps, and filters. Fuel is stored in specialized tanks that prevent leakage and contamination. Pumping systems must maintain specific pressures to ensure steady fuel flow. However, ensuring such precision is challenging. Minor leaks or blockages can cause serious delays or safety issues. Regular inspections and maintenance records show that up to 15% of fuel systems may require immediate repairs or upgrades.

Fuel management also plays a significant role. Pilots must monitor fuel levels and consumption closely. Discrepancies can lead to critical situations in flight. In fact, data from the Federal Aviation Administration indicates that improper fuel management accounts for about 10% of aviation accidents. These issues highlight the ongoing challenges in maintaining optimal fuel systems and the need for constant improvement in aviation safety protocols.

Types of Aviation Fuel Systems Used in Modern Aircraft

Modern aircraft rely on a variety of aviation fuel systems to ensure efficient and safe operation. These systems can be broadly categorized into two types: gravity-fed and fuel pump systems. Gravity-fed systems rely on the natural pull of gravity to move fuel from the tanks to the engines. They are simple and effective, but their efficiency can be limited by altitude and fuel tank placement.

Fuel pump systems, on the other hand, utilize powerful pumps to draw fuel from the tanks. This allows for greater control over fuel distribution and pressure, enabling optimal engine performance. Within these systems, you’ll find both mechanical and electrical pumps. Each type has advantages and disadvantages. Mechanical pumps are robust and reliable but can be less efficient at high altitudes. Electrical pumps are more versatile but may introduce points of failure.

However, the complexity of these systems can lead to challenges. For instance, fuel contamination remains a key concern. Ensuring the purity of fuel is crucial, but it's often overlooked. Maintenance and checks are essential, yet they can be cumbersome. Sometimes, the focus on one aspect can lead to neglect in others. Balancing efficiency with safety remains an ongoing task in aviation fuel management.

Key Components of Aviation Fuel Systems and Their Functions

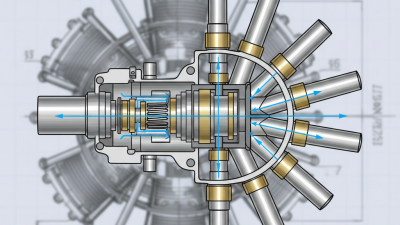

Aviation fuel systems play a crucial role in powering modern aircraft. These systems manage the storage, transfer, and delivery of fuel. They consist of several key components that ensure efficient operation and safety during flights.

Fuel tanks are the most visible part of the system. They store large quantities of fuel, but their design is not without issues. Many tanks can be challenging to maintain, leading to potential contamination. This risk can affect fuel quality and engine performance. Regular inspection and cleaning are essential to prevent these problems.

Fuel pumps are another critical component. They transport fuel from the tanks to the engines. High-performance aircraft often require multiple pumps for redundancy. However, their complexity can lead to reliability concerns. According to industry reports, approximately 20% of in-flight failures in older aircraft are related to fuel system malfunctions. Monitoring technology advancements in fuel pumps can help mitigate these issues.

Fuel filters play a vital role in keeping contaminants at bay. They remove particles and water from the fuel, ensuring a clean supply to the engine. A clogged filter can lead to suboptimal engine performance or even failure. Awareness of these risks is necessary for aviation safety. Overall, while aviation fuel systems are designed to be robust, continuous evaluations and improvements are needed for optimal performance.

| Component | Function | Material | Typical Application |

|---|---|---|---|

| Fuel Tank | Stores aviation fuel securely | Aluminum | Commercial aircraft |

| Fuel Pump | Delivers fuel from the tank to the engine | Stainless Steel | Jet engines |

| Fuel Filter | Removes impurities from fuel | Plastic and Metal | Aircraft systems |

| Fuel Gauge | Indicates fuel level in the tank | Glass and Metal | Cockpit instrumentation |

| Fuel Injection System | Mixes fuel with air for combustion | Aluminum and Plastic | Turbofan engines |

Operational Mechanisms of Aviation Fuel Systems Explained

Aviation fuel systems are complex yet crucial for aircraft operations. These systems ensure that fuel is efficiently stored and delivered to engines. Pressure and temperature can impact fuel performance. A well-designed fuel system should handle these variables.

Fuel tanks are typically located in the wings or fuselage. Pumps move the fuel, while valves control the flow. Filters catch impurities, ensuring clean fuel reaches the engine. Monitoring fuel levels is vital. An imbalance can lead to engine issues.

**Tip:** Regular inspections can prevent problems. Ensure all components are functioning properly. Neglecting routine checks may lead to inefficient performance.

The operational mechanism of aviation fuel systems requires careful coordination. Each part must work in harmony. Any malfunction can cause delays or even emergencies. It's essential to understand how these components interact with each other.

**Tip:** Keep records of maintenance. This helps track system performance over time. Small issues can escalate if ignored.

While aviation fuel systems are designed to be reliable, challenges remain. Understanding the intricacies can lead to better solutions. Continuous improvement is needed to enhance effectiveness and safety.

2026 Best Aviation Fuel Systems Performance Overview

Future Trends and Innovations in Aviation Fuel Technologies

The future of aviation fuel technologies is rapidly evolving. Innovations in biofuels, synthetic fuels, and hydrogen are leading the way. According to industry reports, the global aviation biofuel market is projected to reach $19.5 billion by 2027. This shift is crucial for reducing carbon emissions. Airlines are under pressure to adopt cleaner fuels.

Hydrogen fuel is gaining traction. It emits only water vapor when burned, promising a cleaner future for aviation. The International Air Transport Association (IATA) aims for net-zero carbon emissions by 2050. Yet, challenges remain. Infrastructure for hydrogen fueling is still developing. Additionally, safety concerns related to hydrogen storage need addressing.

Tips: Consider the energy density of different fuels. Fuel efficiency is key to reducing costs and emissions. The shift to sustainable aviation fuels is essential for the industry's future. However, it requires collaboration across sectors. Stakeholders must invest in research and development. Embracing these innovations could reshape how airlines operate.

Related Posts

-

Why Understanding Aviation Fuel Systems is Crucial for Efficient Flight Operations

-

Exploring the Future of Aviation: How Kit Aircraft are Redefining DIY Flight for Enthusiasts

-

Exploring the Future of Fuel Injection Aircraft: Innovations and Advancements in Aviation Technology

-

Understanding the Future of Aviation Fuel Innovations and Their Impact on Air Travel

-

What is a Fuel Flow Divider and How Does It Work in Aircraft Engines?

-

Top 10 Essential Aircraft Systems Every Pilot Should Understand