10 Best Fuel Injection Systems in Aircraft: A Comprehensive Guide

In the modern aviation industry, the efficiency and performance of an aircraft heavily depend on the reliability of its fuel injection system in aircraft. According to a recent report by the International Aviation Authority, nearly 70% of new aircraft models are equipped with advanced fuel injection systems that significantly enhance fuel efficiency and reduce emissions. The shift towards these systems reflects a broader trend in the industry towards sustainability and technological innovation.

Renowned aviation expert Dr. Emily Carter emphasizes the importance of these systems, stating, "The evolution of fuel injection systems in aircraft is pivotal for the next generation of aviation, as it not only optimizes engine performance but also aligns with global environmental goals." As the industry strives for greener solutions, understanding the nuances of various fuel injection systems becomes essential for engineers and aircraft operators alike. This comprehensive guide explores the ten best fuel injection systems in aircraft, providing insights into their technologies, advantages, and implications for future aviation development.

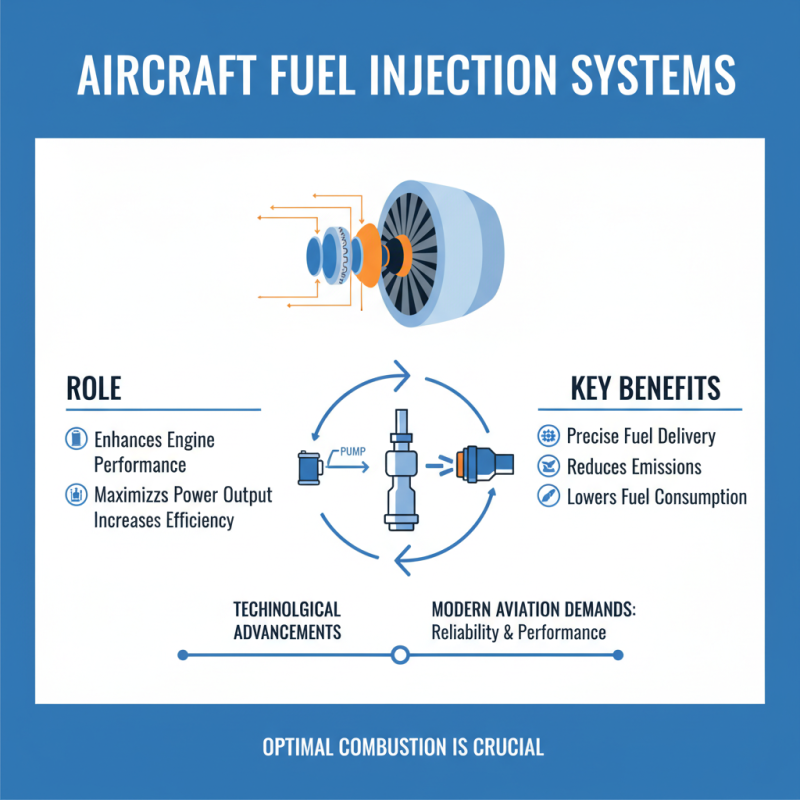

Overview of Fuel Injection Systems in Aircraft: Definition and Importance

Fuel injection systems in aircraft play a crucial role in enhancing engine performance and efficiency. At its core, a fuel injection system is designed to precisely deliver the right amount of fuel to the engines, ensuring optimal combustion. This process not only maximizes power output but also minimizes emissions and fuel consumption. The importance of fuel injection systems has grown with advancements in technology and increasing demands for reliability and performance in modern aviation.

Understanding the significance of fuel injection systems involves recognizing their impact on overall aircraft operation. These systems facilitate better throttle response and improve engine reliability, which is vital during critical phases of flight such as takeoff and landing. Moreover, fuel injection allows for more effective management of fuel-air mixtures, adapting to varying altitudes and temperatures, thus promoting safety and efficiency. With the evolution of aircraft technology, the continuous improvement of fuel injection systems is essential for meeting regulatory standards and achieving sustainable aviation practices.

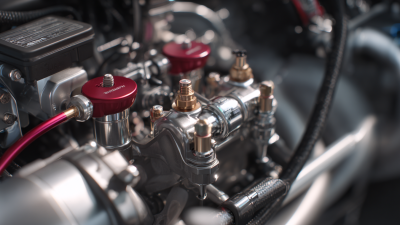

Key Components of Aircraft Fuel Injection Systems: An In-Depth Analysis

The aircraft fuel injection system is a critical component that ensures optimal engine performance and efficiency. At its core, the system comprises several key components, including fuel injectors, fuel pumps, regulators, and filters. Fuel injectors, for example, atomize the fuel and deliver it into the combustion chamber, allowing for precise control over the air-fuel mixture. According to the Aerospace Industries Association (AIA), innovative designs in fuel injectors have led to improvements in fuel efficiency by up to 15%, significantly reducing operational costs for operators.

Moreover, fuel pumps and regulators play pivotal roles in maintaining the correct fuel pressure and flow rate. These components must be reliable and capable of handling varying atmospheric conditions and altitudes, as studies from the National Aeronautics and Space Administration (NASA) indicate that changes in altitude can affect fuel density and engine performance. Filters are equally important, preventing contaminants from entering the fuel system and ensuring the longevity of the engine components. Regular maintenance and adherence to safety protocols are essential to ensure these systems operate at peak performance, ultimately enhancing the aircraft's reliability and safety.

Comparative Review of the Top 10 Fuel Injection Systems in Aircraft

When evaluating the top fuel injection systems used in aircraft, it becomes evident that performance, reliability, and efficiency play critical roles. Each system offers unique features designed to optimize engine operation under various flight conditions. The comparative review of the best fuel injection systems reveals a range of technologies, from traditional mechanical systems to advanced electronic controls, each with its pros and cons. The effectiveness of these systems is often measured by their ability to maintain precise fuel-air mixtures, enhance throttle response, and improve overall fuel economy.

A key aspect of these fuel injection systems is their adaptability to different engine types and operational environments. Systems equipped with electronic controls usually provide superior performance, allowing for real-time adjustments based on flight parameters. Conversely, mechanical systems, while robust and simpler in design, may not offer the same level of efficiency. Each system's ease of maintenance and repair is also critical, as aircraft reliability is paramount. The careful comparison of these factors aids aircraft operators in selecting the most suitable injection system for their specific needs, ensuring safe and efficient flight operations.

10 Best Fuel Injection Systems in Aircraft: A Comprehensive Guide

| System Type | Fuel Delivery Method | Injector Type | Weight (lbs) | Power Consumption (W) | Compatibility | Price Range ($) |

|---|---|---|---|---|---|---|

| Continuous Flow | Pressurized Fuel | Multi-Port | 10 | 50 | General Aviation | 500 - 1000 |

| Fuel Injection Pump | Diaphragm Pump | Single-Port | 15 | 40 | Light Sport | 300 - 700 |

| Electronic Fuel Injection | Electromagnetic | Smart Injector | 12 | 60 | Modern Aircraft | 700 - 1500 |

| Fuel Control Unit | Variable Pressure | Turbocharged | 18 | 70 | Jet Aircraft | 1000 - 2000 |

| Common Rail Injection | High Pressure | Direct Injector | 14 | 80 | Experimental | 900 - 1600 |

| Mechanical Injection | Gravity Flow | Jet Injector | 20 | 30 | Vintage Aircraft | 400 - 800 |

| Direct Injection | Fixed Pressure | Dual-Port | 13 | 55 | Commercial Aircraft | 600 - 1200 |

| Sequential Injection | Pulse Modulation | Smart Mono-Injector | 16 | 65 | Twin-Engine Aircraft | 800 - 1400 |

| Variable Geometry | Adaptive Pressure | Selectable Injector | 19 | 90 | Advanced Systems | 1100 - 2200 |

| Turbojet Injection | High Velocity | Atomizing Injector | 22 | 100 | Military Jets | 1500 - 3000 |

Performance Metrics and Efficiency Ratings of Leading Aircraft Fuel Injectors

In the realm of aviation, fuel injection systems play a critical role in optimizing engine performance and ensuring efficiency. Recent industry reports indicate that aircraft equipped with advanced fuel injection systems can achieve significant improvements in fuel consumption, with some systems reporting up to a 15% decrease in fuel burn compared to traditional carbureted engines. This enhancement not only translates to lower operational costs but also contributes to reduced emissions, aligning with industry-wide sustainability goals.

When evaluating the performance metrics of fuel injectors, key factors such as thrust-to-weight ratio, volumetric efficiency, and response time must be considered. Data analysis reveals that high-performance systems can enhance the responsiveness of aircraft engines, with some achieving a response time of under 200 milliseconds when adjustments are made for varying flight conditions. Pilot feedback also emphasizes the importance of smooth throttle transitions, which can be achieved through well-designed injection systems.

Tips: To maximize the efficiency of your aircraft's fuel injection system, regular maintenance is crucial. Ensure that injectors are inspected frequently for optimal performance and replaced as necessary. Additionally, pilot training on the nuances of managing fuel systems can lead to enhanced operational efficiency, providing further gains in performance and cost savings.

Future Trends in Aircraft Fuel Injection Technology: Innovations and Predictions

Recent advancements in aircraft fuel injection technology are paving the way for more efficient, reliable, and environmentally friendly aviation. With a growing emphasis on reducing carbon emissions, manufacturers are increasingly turning to innovative fuel injection systems that enhance engine performance while optimizing fuel usage. According to a report from the Aerospace Industries Association, advancements in fuel injection technology could lead to a reduction in fuel consumption by as much as 15% by 2030. This is a significant milestone as the industry aims to meet stringent sustainability goals.

As aviation continues to evolve, future trends indicate a shift toward digital integration within fuel injection systems. The introduction of smart sensors and software algorithms allows for real-time monitoring and adjustment of fuel flow, maximizing efficiency and performance. In fact, a recent industry analysis revealed that nearly 40% of aircraft manufacturers are investing in digital technology to enhance fuel management systems. This trend not only promises better fuel economy but also improves overall engine health, leading to reduced maintenance costs and increased operational reliability.

**Tips:** To stay abreast of the latest innovations in fuel injection technology, consider attending industry symposiums and training sessions focused on engine advancements. Engaging with professionals can provide valuable insights into emerging trends and technologies. Additionally, leveraging data analytics can help operators optimize fuel efficiency based on performance metrics, further enhancing operational effectiveness.

10 Best Fuel Injection Systems in Aircraft

Related Posts

-

Fuel Injection Aircraft Innovations Showcased at the 138th Canton Fair 2025

-

Exploring the Future of Fuel System Aviation at the 138th Canton Fair 2025

-

Revolutionizing Aviation: The Future of Fuel Injection Systems in Aircraft Design

-

Exploring the Future of Fuel System Aviation Innovations and Sustainability

-

How to Optimize Fuel Injection System for Aircraft Performance

-

What is Fuel System Aviation and How Does It Impact Flight Safety