How to Optimize Fuel Injection in Aviation for Improved Performance and Efficiency

In the realm of aviation, optimizing fuel injection is paramount not only for enhancing aircraft performance but also for improving overall efficiency. Fuel injection aviation technology plays a crucial role in the way modern aircraft engines operate, impacting everything from fuel consumption to emission levels. As the demand for greener and more efficient flying solutions continues to rise, the need to refine fuel injection systems has never been more pressing.

This introduction to fuel injection aviation delves into the various methods and strategies that can be employed to maximize the potential of fuel injection systems in aircraft. From advanced computational modeling to innovative fuel delivery techniques, the quest for optimization is multifaceted. By understanding the intricate relationship between fuel injection performance and operational efficiency, engineers and aviation professionals can develop solutions that not only meet regulatory standards but also enhance the flying experience.

As we explore the intricacies of fuel injection in aviation, we will highlight current trends, challenges, and the latest technological advancements that are paving the way for a more efficient future in air travel. Ultimately, the goal is to equip the aviation industry with the knowledge and tools necessary to push the boundaries of what is possible, ensuring that fuel injection systems can adapt to the evolving demands of modern aviation.

Understanding the Basics of Fuel Injection Systems in Aviation

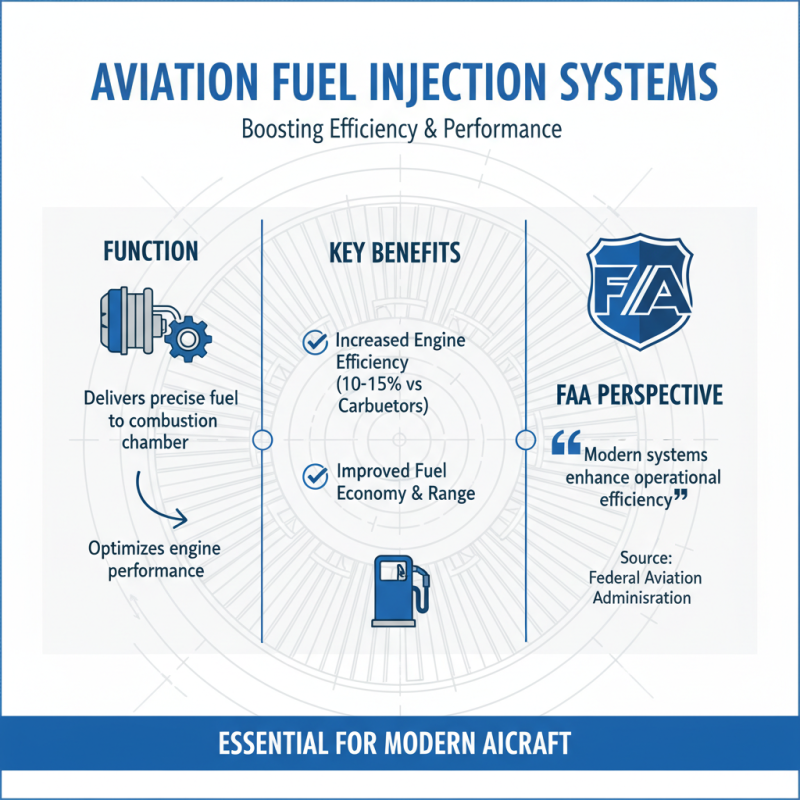

Fuel injection systems play a critical role in aviation, significantly influencing the performance and efficiency of aircraft engines. These systems are responsible for delivering the precise amount of fuel into the combustion chamber, ensuring optimal engine performance. Understanding the basics of these systems is essential for any aerospace engineer or operator looking to enhance operational efficiency. According to the Federal Aviation Administration (FAA), modern fuel injection systems can lead to a 10-15% increase in engine efficiency compared to older carburetor systems, highlighting the importance of technology in aviation advancements.

At the core of fuel injection systems are various components, including injectors, fuel pumps, and electronic control units. The injectors atomize fuel, allowing for better mixing with air, which is crucial for efficient combustion. The electronic control units optimize fuel delivery based on real-time engine data, leading to improvements in throttle response and overall fuel efficiency. A study conducted by the National Aeronautics and Space Administration (NASA) indicated that properly calibrated fuel injection systems can reduce fuel consumption by as much as 20%, translating into significant cost savings for operators and reduced environmental impact.

Furthermore, as the aviation industry continues to evolve, the integration of advanced diagnostic tools and simulation models is enhancing the understanding of fuel injection systems. These tools enable engineers to analyze system performance and identify areas for optimization. Research from the International Air Transport Association (IATA) suggests that optimizing fuel injection systems not only improves aircraft performance but also contributes to overall fleet sustainability efforts by lowering carbon emissions, aligning the industry with global environmental goals.

Key Factors Affecting Fuel Injection Performance and Efficiency

Optimizing fuel injection in aviation

is crucial for enhancing overall performance and improving fuel efficiency. Numerous key factors influence fuel injection system performance, including injector design, fuel quality, and environmental conditions. According to the Aviation Fuel Quality Control Reports, the use of high-quality fuels with proper additives can improve atomization and combustion efficiency, leading to up to a

5% increase in fuel efficiency.

Additionally, the design of fuel injectors plays a significant role; modern injectors with advanced nozzle designs can achieve better fuel spray patterns, which enhance mixing and combustion, thus maximizing engine performance.

Another critical aspect is the precise control of the fuel injection timing and quantity. Advanced engine management systems utilize real-time data to optimize injection parameters, adjusting them based on altitude, temperature, and engine load.

Studies from the Aerospace Engineering Journal indicate that optimizing fuel injection timing can lead to a significant reduction in emissions, with potential decreases of

10-15% in NOx emissions under certain operating conditions. Furthermore, regular maintenance and calibration of fuel injection systems are essential to ensure they operate at peak efficiency, demonstrating that both technological advancements and operational diligence significantly affect fuel injection performance in aviation.

Techniques for Optimizing Fuel Injection Settings in Aircraft Engines

Optimizing fuel injection settings in aircraft engines is crucial for enhancing overall performance and efficiency. One effective technique involves adjusting the fuel-air mixture to achieve optimal combustion. This can be done through modifications in the engine’s electronic control unit (ECU) that monitor and regulate the fuel delivery based on various parameters such as altitude, temperature, and engine load. By fine-tuning these settings, pilots can ensure that the engine operates within its ideal performance range, reducing fuel consumption while maximizing thrust.

Another approach is the implementation of advanced fuel injection technologies, such as sequential fuel injection or direct injection systems. These systems allow for more precise timing and quantity of fuel injected into the combustion chamber, leading to improved fuel atomization and combustion efficiency. Additionally, employing real-time data analytics can help monitor the engine’s performance, enabling maintenance crews to make timely adjustments to the fuel injection settings. By leveraging data from engine sensors, they can identify optimal settings that enhance efficiency and performance while minimizing emissions and operating costs.

The Role of Fuel Quality in Enhancing Aviation Engine Performance

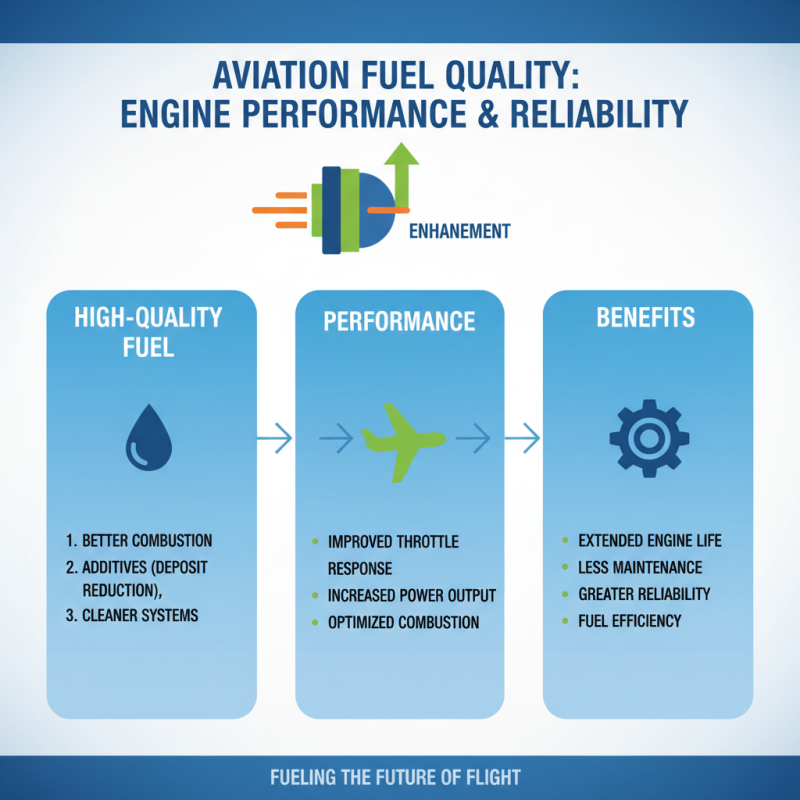

Fuel quality plays a crucial role in enhancing aviation engine performance, impacting both efficiency and reliability. High-quality fuel contributes to better combustion characteristics, which translate to improved throttle response and overall engine power output. The presence of additives in superior fuels can further reduce the formation of deposits on engine components, maintaining cleaner fuel systems and optimizing the combustion process. This leads to not only heightened performance but also extended engine life, minimizing the need for maintenance and repairs.

In addition to the chemical composition, the physical properties of fuel, such as its density and viscosity, are pivotal in the fuel injection process. Proper atomization is essential for efficient combustion; thus, fuels with suitable properties can significantly enhance the effectiveness of injectors. This fine balance allows for the precise delivery of fuel into the combustion chamber, ensuring a more complete burn and lower emissions. Consequently, prioritizing fuel quality is essential for aviation operators aiming to boost engine performance while adhering to environmental standards.

Future Trends in Fuel Injection Technology for Aviation Efficiency

The future of fuel injection technology in aviation is set to revolutionize performance and efficiency as the industry increasingly embraces digitalization and advanced materials. With nearly 60% of an aircraft’s operational costs attributed to fuel expenditure, optimizing fuel injection systems is essential for lowering expenses and enhancing sustainability. According to a report by the International Air Transport Association (IATA), fuel efficiency improvements of up to 15% can be realized through the implementation of smart fuel management systems that utilize data analytics and real-time adjustments to injector performance.

Emerging trends also include the adoption of additive manufacturing and advanced fuel injection techniques such as direct injection. Research from the National Aeronautics and Space Administration (NASA) highlights that these innovative methods can improve combustion efficiency and reduce emissions by as much as 20%. Furthermore, the integration of hybrid electric propulsion systems is gaining traction, indicating a shift in focus toward greener technologies. As the sector moves forward, the development of next-generation fuel pumps and injectors designed for alternative fuels, including biofuels and synthetic options, will play a critical role in achieving net-zero emissions targets by 2050, as outlined in the Global Aviation Climate Action Plan.

Related Posts

-

Exploring the Future of Fuel System Aviation Innovations and Sustainability

-

Exploring the Future of Fuel System Aviation at the 138th Canton Fair 2025

-

What is Fuel System Aviation and How Does It Impact Flight Safety

-

How to Optimize Fuel Injection in Aviation for Better Performance and Efficiency

-

10 Best Fuel Injection Systems in Aircraft: A Comprehensive Guide

-

Understanding the Future of Aviation Fuel Innovations and Their Impact on Air Travel