How to Troubleshoot and Maintain Fuel Injection Systems in Aircraft

The fuel injection system in aircraft plays a crucial role in ensuring optimal engine performance and efficiency. It is responsible for delivering the right amount of fuel to the combustion chamber while maintaining precise timing, which is essential for smooth operation and fuel economy. However, like any complex mechanism, fuel injection systems can encounter various issues that may affect their functionality. Understanding how to troubleshoot and maintain these systems is vital for pilots and aircraft maintenance personnel alike.

Proper maintenance of the fuel injection system in aircraft not only enhances performance but also extends the lifespan of the engine. Regular inspections, timely repairs, and an understanding of potential issues can significantly reduce the risk of in-flight failures. This article will provide valuable insights into effective troubleshooting techniques and maintenance practices that can help keep fuel injection systems operating at peak levels. By mastering these skills, aviation professionals can ensure the reliability and safety of their aircraft, ultimately contributing to a more efficient aviation industry.

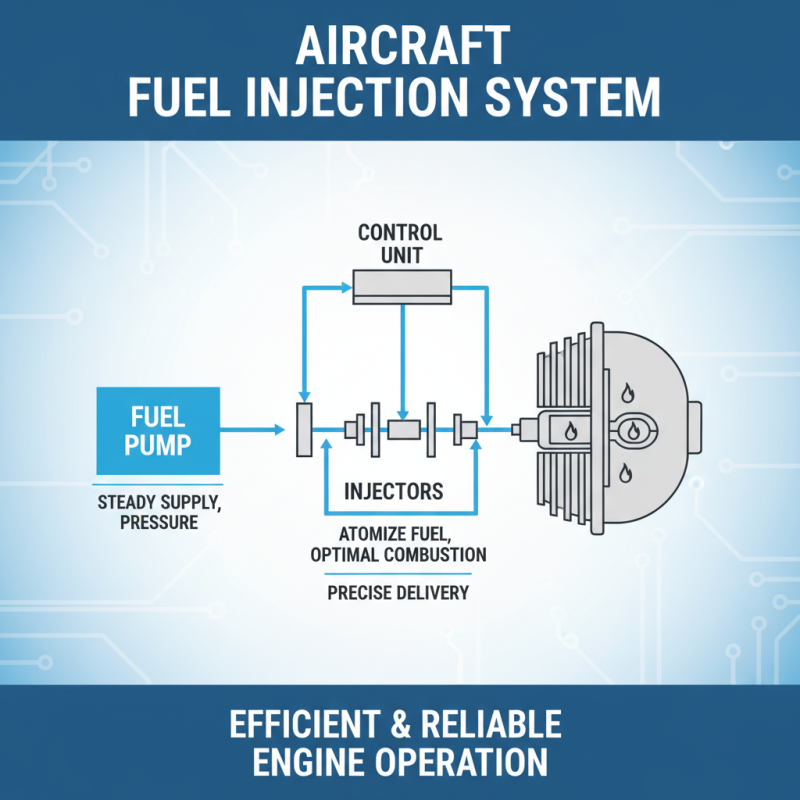

Understanding the Basics of Aircraft Fuel Injection Systems and Components

Aircraft fuel injection systems are critical for the efficient and reliable operation of aviation engines. These systems are designed to deliver precise amounts of fuel directly into the combustion chamber. At the heart of the fuel injection system are key components such as the fuel pump, injectors, and control units. The fuel pump ensures a steady supply of fuel at the required pressure, while the injectors atomize the fuel for optimal combustion. Understanding these components and their functions is essential for effective troubleshooting and maintenance.

Tips:

1. Regularly inspect fuel lines and connections for leaks or blockages. Ensure that all components are clean and free of debris.

2. Pay attention to the fuel filter, as a clogged filter can significantly affect performance. Replacing it at recommended intervals is crucial for system health.

3. Use diagnostic tools to monitor system parameters and identify any irregularities. This proactive approach helps in catching issues before they escalate.

By keeping a close eye on these elements, you can maintain the efficiency of your aircraft’s fuel injection system and ensure safer flights.

Common Issues and Symptoms in Aircraft Fuel Injection Systems

Aircraft fuel injection systems play a critical role in ensuring optimal engine performance and efficiency. However, several common issues can arise, affecting system functionality. One of the most prevalent problems is fuel starvation, often characterized by symptoms such as rough engine idling, diminished power output, and an increase in engine temperatures. According to the Aircraft Owners and Pilots Association (AOPA), inadequate fuel delivery can lead to increased wear on engine components and, ultimately, catastrophic engine failure if not promptly addressed.

Another significant concern is injector fouling, where deposits build up within the fuel injector nozzles, disrupting the fine mist of fuel needed for efficient combustion. Symptoms of injector fouling include a noticeable decrease in throttle response, engine misfires, and excessive fuel consumption, which can adversely affect overall flying performance. The National Transportation Safety Board (NTSB) reports that a sizeable percentage of engine-related incidents in general aviation can be traced back to fuel system malfunctions, emphasizing the importance of routine maintenance and monitoring for these symptoms to enhance both safety and operational efficiency.

Regular inspection and maintenance of fuel injection systems are paramount in mitigating these common issues. Operators should be aware of the signs indicating a failing system and follow manufacturer guidelines for service intervals, as research indicates that systems failing to undergo preventive measures can see a significant increase in operational costs and decreased aircraft reliability. By remaining vigilant and proactive, operators can ensure the longevity and efficiency of their aircraft fuel injection systems.

Common Issues and Symptoms in Aircraft Fuel Injection Systems

Step-by-Step Troubleshooting Techniques for Fuel Injection Systems

When troubleshooting fuel injection systems in aircraft, it is essential to adopt a systematic approach. Start by gathering information about the specific symptoms observed during operation—this could include issues such as engine roughness, poor fuel economy, or difficulty starting. Once you have this preliminary data, consult the aircraft's maintenance manual for the recommended procedures and specifications. This will serve as your guide, ensuring you are aware of the normal operational parameters for the fuel injection system.

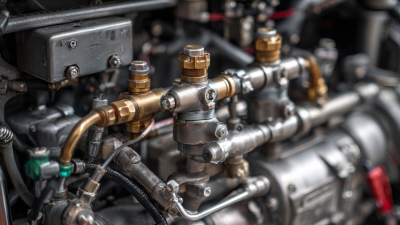

The next step is to visually inspect the fuel injection components, including fuel lines, injectors, and filters, for signs of damage or blockages. Pay close attention to any leaks, which can indicate a failing component that needs replacement. Use diagnostic tools to check fuel pressure and verify that it aligns with the manufacturer's specifications. Additionally, assess the electronic controls related to the fuel injection system; a malfunction in these systems can lead to incorrect fuel delivery, and addressing any electronic issues is crucial for restoring optimal performance. Remember to document each step of your troubleshooting process for future reference and to establish a reliable maintenance routine that keeps the fuel injection system functioning smoothly.

Routine Maintenance Practices to Ensure Optimal Fuel Injection Performance

Routine maintenance is critical for ensuring optimal performance of fuel injection systems in aircraft. Regular inspections of fuel injectors can prevent issues such as clogging, which can severely impact engine performance. According to the Aerospace Industries Association, a well-maintained fuel injection system can improve fuel efficiency by up to 15%. This efficiency gain not only saves costs but also contributes to lower emissions, aligning with the increasing demand for sustainable aviation practices.

To maintain an efficient fuel injection system, establishing a scheduled maintenance routine is essential. Maintenance tasks should include checking for fuel leaks, ensuring proper electrical connections, and cleaning the injectors regularly. An annual check-up is recommended, but pilots and maintenance crews should remain vigilant for signs of irregular performance, such as engine roughness or increased fuel consumption.

Tips for Maintaining Fuel Injection Systems:

- Conduct regular diagnostics to identify any sensor or fuel delivery issues early on.

- Replace fuel filters according to manufacturer guidelines, typically every 100 hours of flight time, to avoid particulates that may accumulate in the injectors.

- Consider using a fuel system cleaner during your maintenance cycles to help prevent deposits from forming, thereby enhancing injector life and performance.

Key Industry Data on Fuel Efficiency and Emissions Impact from Injection Systems

Fuel injection systems play a crucial role in enhancing fuel efficiency and minimizing emissions in aircraft operations. The efficiency of these systems can significantly impact the overall environmental footprint of aviation, making it essential for operators and maintenance personnel to understand their function and performance metrics. Key industry data indicates that modern fuel injection technologies can improve fuel efficiency by up to 15%, resulting in substantial cost savings and reduced greenhouse gas emissions. By delivering precise fuel quantities at optimal timing, these systems ensure better combustion, leading to lower unburned hydrocarbons and particulate matter released into the atmosphere.

Moreover, the implementation of advanced fuel injection strategies, such as variable geometry nozzles and electronic control units, allows for fine-tuning of the fuel-air mixture across various flight conditions. This adaptability not only contributes to improved engine efficiency but also helps in meeting increasingly stringent emissions regulations. Current studies suggest that proactive maintenance of fuel injection systems is vital, as even minor malfunctions can lead to significant increases in fuel consumption and emissions. Addressing these issues through regular diagnostics and adjustments can ensure that aircraft remain compliant with environmental standards while optimizing operational costs.

How to Troubleshoot and Maintain Fuel Injection Systems in Aircraft - Key Industry Data on Fuel Efficiency and Emissions Impact from Injection Systems

| Metric | Value | Impact |

|---|---|---|

| Fuel Efficiency (MPG) | 25 | Improved performance with optimized injection |

| Emissions (g CO2/km) | 350 | Reduction through advanced injector technology |

| Injector Maintenance Interval (hours) | 500 | Critical for preserving fuel economy |

| Common Issues Detected | Clogging, Leaking | Direct impact on engine performance |

| Fuel System Inspection Frequency (months) | 6 | Ensure system integrity and performance |

| Pilot Awareness Training (hours) | 2 | Enhances operational safety |

Related Posts

-

Fuel Injection Aircraft Innovations Showcased at the 138th Canton Fair 2025

-

How to Optimize Fuel Injection System for Aircraft Performance

-

10 Best Fuel Injection Systems in Aircraft: A Comprehensive Guide

-

Understanding the Evolution of Aircraft Service: From Maintenance to Passenger Experience

-

10 Essential Tips for Beginners in General Aviation to Enhance Your Skills

-

How to Get Started in Experimental Aviation: A Beginner's Guide