Top Aviation Manufacturing Trends to Watch in 2026?

As we look toward 2026, the aviation manufacturing industry stands at a pivotal crossroads. According to Emily Johnson, a leading expert in aviation innovation, "The future of aviation manufacturing hinges on adaptability and sustainability." This statement underscores the pressing need for manufacturers to evolve as new technologies and regulations emerge.

In recent years, we have witnessed a surge in the integration of advanced technologies like AI and additive manufacturing. These innovations promise increased efficiency but also present challenges. For instance, adapting traditional workflows to incorporate automation can be difficult. It's crucial for companies to strike a balance, embracing new tools while maintaining quality and safety standards.

Furthermore, sustainability remains a hot topic. As environmental concerns grow, aviation manufacturing must rethink its approaches. However, transitioning to greener practices often encounters resistance. Companies must reflect on their existing methods and be willing to make hard changes. The journey toward an eco-friendly future is fraught with obstacles, but it is a necessary path. The landscape of aviation manufacturing is shifting, and those who adapt will thrive.

Emerging Technologies Shaping the Future of Aviation Manufacturing

The future of aviation manufacturing is rapidly evolving. Emerging technologies are set to redefine production processes. According to recent studies, 73% of manufacturers are investing in automation to enhance efficiency. Robotics is at the forefront of this shift. Their precision minimizes waste and speeds up production timelines.

3D printing is another game-changer. It allows for complex parts to be created quickly and efficiently. Reports suggest that by 2025, 3D printing could cut production costs by up to 30%. However, the technology's integration is not without challenges. Many manufacturers struggle with quality control and regulatory compliance.

Tips: Embrace change. Investigate new technologies that fit your production needs. Continual training is essential for staff. Regular updates on tech trends can keep your business competitive. Be aware of the potential pitfalls while adopting these technologies. Focus on scalability and flexibility to adapt to market shifts.

Sustainability Initiatives in Aerospace Production by 2026

As we look toward 2026, sustainability in aerospace production stands at the forefront of industry trends. Aerospace manufacturers are increasingly adopting eco-friendly practices. Emissions reduction strategies are becoming essential. Companies are investing heavily in cleaner technologies and alternative materials. Sustainable aviation fuels are gaining traction, but their production still faces challenges.

The transition to a circular economy is also crucial. Many producers are exploring ways to recycle and reuse materials. However, the process isn't without complications. Some materials are difficult to repurpose. Energy consumption remains a significant concern, especially in production phases. Innovations in energy efficiency are necessary, yet they often require upfront investments that some may hesitate to make.

Collaboration within the industry is vital. It encourages knowledge sharing that can lead to new sustainable solutions. Regulatory pressures are an ongoing challenge. Companies must navigate compliance while innovating. The path to sustainability is fraught with hurdles, demanding creativity and commitment. Acknowledging these imperfections is the first step toward a greener future in aerospace production.

Top Aviation Manufacturing Trends to Watch in 2026: Sustainability Initiatives in Aerospace Production by 2026

| Trend | Description | Expected Impact | Implementation Year |

|---|---|---|---|

| Use of Sustainable Materials | Increased use of bio-based and recycled materials in aircraft components. | Reduction in carbon footprint and waste generation. | 2026 |

| Carbon Neutral Manufacturing | Initiatives to offset emissions from manufacturing processes. | Movement towards net-zero manufacturing operations. | 2026 |

| Energy Efficiency Innovations | Adoption of advanced energy-efficient technologies and practices in production. | Significant reduction in energy consumption. | 2026 |

| Digital Twin Technology | Use of digital simulations for optimizing production processes. | Enhanced efficiency and reduced resource waste. | 2026 |

| Circular Economy Practices | Implementing recycling and reuse strategies within the production cycle. | Minimized environmental impact and resource consumption. | 2026 |

Impact of Advanced Robotics on Aircraft Assembly Processes

The aviation manufacturing sector is undergoing a significant transformation, particularly in aircraft assembly. Advanced robotics are becoming crucial in this evolution. By 2026, it's projected that robotics will enhance assembly line efficiency by up to 30%. This forecast stems from a 2023 industry report detailing how automation reduces human error and increases precision. Robotic arms now handle tasks like fuselage assembly with remarkable accuracy.

However, the integration of robotics is not without challenges. Many companies grapple with high initial costs and the need for skilled operators. A significant barrier remains the workforce adaptation. Reports indicate that up to 60% of workers need retraining to work effectively alongside robots. The dynamics of human-robot collaboration require constant adjustment and monitoring. It's essential to reflect on the balance between technology and human input. While robots excel at repetitive tasks, creativity and problem-solving still lay in human hands.

Moreover, environmental concerns are also emerging. Some automated processes consume substantial energy. Companies must address this issue to maintain sustainability. Research indicates that improving energy efficiency in robotic applications could cut operational costs by 20%. This reflects the industry's dual challenge: embracing technology while remaining vigilant about environmental impact. Balancing innovation and responsibility will pave the way for a successful future in aviation manufacturing.

The Role of Digital Twins in Aviation Manufacturing Efficiency

Digital twins are transforming aviation manufacturing. These virtual models mirror real-world aircraft and components. They help in predicting issues before they arise. For example, a manufacturer can test a design change digitally. This reduces the risks associated with physical alterations.

Data collected from actual flight operations feeds the digital twin. Engineers gain insights into performance and maintenance needs. Adjustments can be made in real-time, enhancing efficiency. However, integration may prove challenging. Not all teams may adapt swiftly to this technology. Training is essential to realize full benefits.

The potential for digital twins is vast, yet imperfect. Not every model will be accurate. Models can diverge from reality, leading to false predictions. Continuous validation and updates are crucial. Companies must invest in refining these systems to optimize their usefulness. Embracing digital twins will require a cultural shift and an openness to change.

Trends in Supply Chain Management for the Aerospace Industry

The aerospace industry is evolving rapidly, especially in supply chain management. By 2026, experts expect a 15% increase in technology adoption within this sector. Automation will play a critical role. Many companies are investing in smart logistics solutions to streamline operations.

Data shows that 67% of aerospace firms struggle with supply chain disruptions. Suppliers often face challenges meeting demand fluctuations. This can lead to delays. Companies are exploring advanced analytics to predict trends and enhance flexibility. Real-time data can help organizations adapt quickly.

The focus on sustainability is growing. According to recent reports, 50% of manufacturers are prioritizing eco-friendly materials. This shift requires changes in sourcing and logistics. While some progress is noted, many struggle with implementing these practices. Supplier collaboration needs improvement for lasting impact.

Related Posts

-

10 Essential Tips for Understanding Aircraft Systems Effectively

-

Top 10 Essential Aircraft Systems Every Pilot Should Understand

-

Top 2025 Fuel Metering Technologies: What You Need to Know

-

10 Essential Tips for Understanding Service Bulletins in Your Industry

-

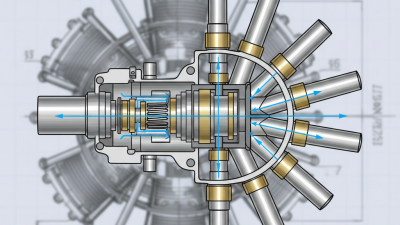

What is a Fuel Flow Divider and How Does It Work in Aircraft Engines?

-

2026 Best Aviation Fuel Options for Sustainable Flight Safety?