How to Improve Fuel Flow for Better Engine Performance?

Improving fuel flow is essential for enhancing engine performance. A consistent and efficient fuel flow ensures optimal combustion, powering the vehicle effectively. However, many vehicle owners may overlook this critical aspect.

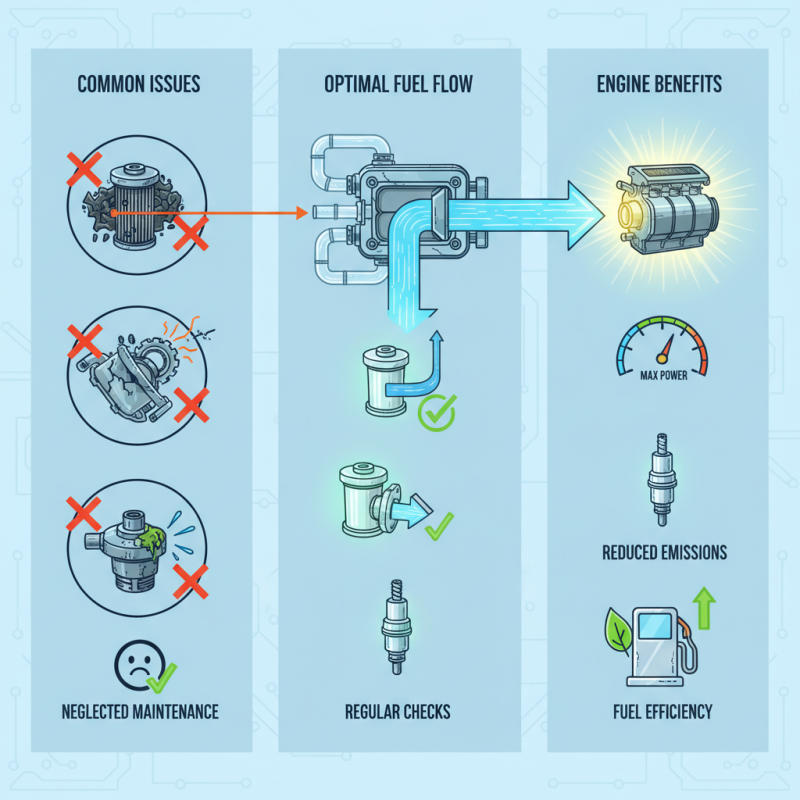

Various factors affect fuel flow. Clogged fuel filters, damaged fuel pumps, and dirty injectors can hinder flow. These issues not only reduce engine power but can also lead to increased emissions. Regular maintenance is often neglected, and it can be easy to forget.

Optimizing fuel flow requires attention to detail. Upgrading components or adopting recommended practices can yield significant benefits. This might include checking for leaks or cleaning the fuel system regularly. Understanding the importance of fuel flow can lead to more informed decisions. A little effort in this area can go a long way.

Understanding the Basics of Fuel Flow in Engine Performance

Fuel flow is crucial for optimal engine performance. When fuel flows smoothly, engines operate efficiently. Poor fuel flow can lead to reduced power and increased emissions. Understanding the basics of fuel flow helps diagnose issues that may impede performance.

Fuel delivery systems, including fuel pumps and injectors, play a vital role in this process. A report from the Society of Automotive Engineers indicates that improper fuel flow can reduce engine efficiency by up to 30%. Regular maintenance ensures these components function correctly. When fuel viscosity changes due to temperature or contamination, performance issues arise.

Tips: Check fuel filters regularly. Clogged filters hamper flow. Use high-quality fuel to minimize buildup. Additionally, consider professional tuning to align the air-fuel ratio for optimal combustion. Regularly inspect your fuel lines for leaks or cracks, as they can significantly affect flow.

Inconsistent fuel flow signals deeper issues within the engine. Problems often go unnoticed until performance drops. Monitoring your fuel system can save time and money in the long run. Awareness is key to maintaining a healthy engine.

How to Improve Fuel Flow for Better Engine Performance

This bar chart illustrates the fuel flow rates at various engine RPM levels, ranging from idle to high RPM. As engine speed increases, fuel flow also increases, which is crucial for optimal engine performance. Understanding this relationship can aid in making necessary adjustments to improve fuel efficiency.

Identifying Factors That Affect Fuel Flow Efficiency

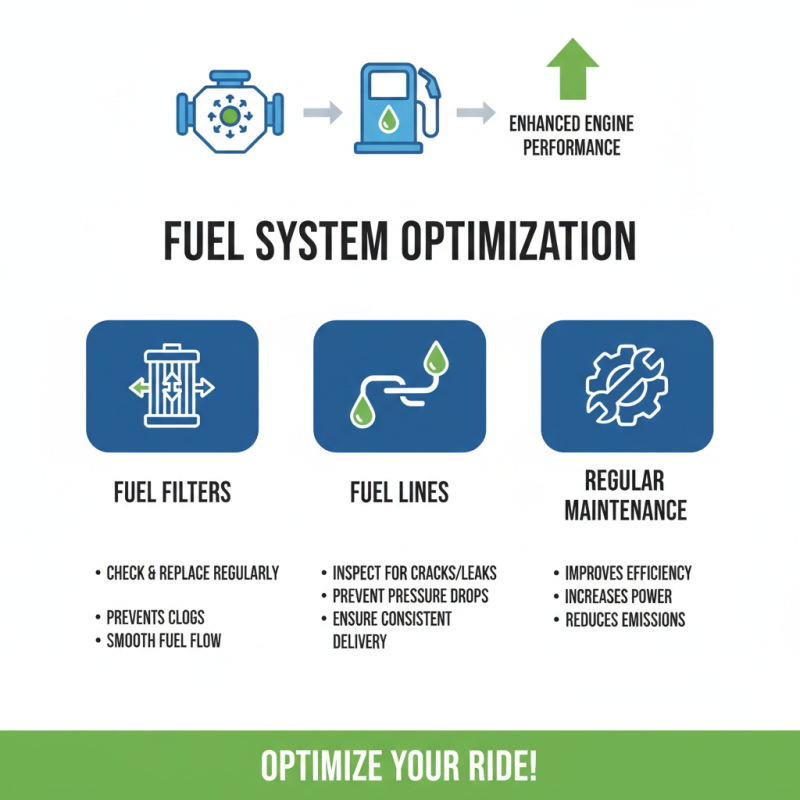

Fuel flow efficiency is crucial for optimal engine performance. Several factors influence how effectively fuel reaches the engine. One significant element is the fuel filter. A clogged filter restricts flow, leading to poor engine response. Regularly checking and replacing the filter can help maintain the desired flow rate.

Another essential factor is the fuel pump's condition. An aging pump may struggle to deliver the required pressure. This can result in fluctuations in engine performance. Keeping an eye on the pump’s efficiency can prevent unexpected issues. Additionally, the quality of the fuel itself plays a role. Contaminants in fuel can disrupt flow and lead to engine knocking. Regular fuel system cleanings can help reduce these risks.

It's also vital to consider the fuel lines. Any bends, leaks, or blockages can hinder flow significantly. Inspecting fuel lines for wear and tear is often overlooked. Engine tuning cannot be ignored either; misconfigured engines will not optimize fuel flow. Reflecting on these details can lead to improved performance, yet many overlook them until a problem arises.

Techniques to Optimize Fuel Delivery Systems

Optimizing fuel delivery systems is essential for enhancing engine performance. Fuel flow directly impacts combustion efficiency. A 2021 report indicated that optimizing fuel injection can improve power output by up to 15%. Such improvements are often achievable through adjustments in fuel pump pressure and injector timing.

Upgrading components can make a significant difference. For instance, upgrading to high-performance fuel injectors allows for finer fuel atomization. This change enhances combustion and allows for better fuel efficiency. Many enthusiasts overlook the importance of a well-calibrated air-fuel ratio. An improper blend can lead to power losses and increased emissions.

Monitoring systems are another vital aspect. A study demonstrated that using real-time data can guide tuning decisions, improving fuel delivery. However, many users fail to take full advantage of these technologies. In doing so, they miss critical insights that could enhance performance. Fuel filters, often neglected, should be checked regularly. Clogged filters can restrict flow, leading to inconsistent engine behavior. Regular maintenance is key to avoid such pitfalls.

How to Improve Fuel Flow for Better Engine Performance? - Techniques to Optimize Fuel Delivery Systems

| Technique | Description | Benefits | Estimated Improvement (%) |

|---|---|---|---|

| Upgrade Fuel Pump | Install a high-performance fuel pump to increase flow rate. | Enhances fuel delivery under high demand conditions. | 10-15% |

| Optimize Fuel Lines | Use larger diameter fuel lines to reduce pressure loss. | Increases efficiency and reduces lag in fuel delivery. | 5-10% |

| Fuel Filter Replacement | Regularly replace the fuel filter to ensure clean fuel flow. | Prevents clogs and improves engine performance. | 2-5% |

| Tuning Fuel Injector | Calibrate fuel injectors for optimal fuel atomization. | Ensures efficient fuel combustion and responsiveness. | 15-20% |

| Regular Fuel Quality Checks | Test fuel for contaminants and octane levels. | Improves overall engine health and performance longevity. | Varies |

Regular Maintenance Practices for Improved Fuel Flow

Regular maintenance practices are essential for improving fuel flow and enhancing engine performance. One crucial step is to check and replace fuel filters regularly. Clogged filters can disrupt fuel flow, leading to engine inefficiency. Inspecting fuel lines for cracks or leaks is also vital. Even small leaks can cause significant performance drops.

Another important aspect is to keep the fuel injectors clean. Dirty injectors can lead to uneven fuel distribution, affecting combustion quality. Using fuel additives periodically can help maintain injector cleanliness. Additionally, timing belt and valve adjustments should not be overlooked. Incorrect timings can create fuel flow issues that hinder performance.

Sometimes, we forget the small things. Keeping the fuel tank filled at least one-quarter helps prevent sediment buildup. This often-overlooked step can significantly impact fuel flow. Addressing these maintenance tasks requires effort, but neglecting them can lead to more serious engine problems down the road.

Upgrading Components for Enhanced Fuel Efficiency

Upgrading components can significantly enhance fuel efficiency in modern engines. One of the critical areas to focus on is the fuel delivery system. Many cars use outdated fuel injectors, which can cause inconsistent flow and reduced performance.

High-performance injectors can improve the atomization of fuel, leading to better combustion. According to a report by the Society of Automotive Engineers, optimizing the fuel injector's design can improve efficiency by up to 30%.

Another essential component is the fuel pump. A weak or inefficient fuel pump can hinder the engine's performance. Replacing the factory-installed pump with a high-capacity model can provide better fuel flow. Research from the American Society of Mechanical Engineers indicates that upgrading to a better pump can increase flow rate by 15%-20%. This change can make a noticeable difference in responsiveness and power output.

Regular maintenance should not be overlooked. Clogged fuel filters can disrupt flow and decrease efficiency. It's suggested to replace fuel filters every 30,000 miles for optimal results. Ignoring this can lead to significant issues down the line. Each component plays a vital role in supporting the system as a whole. Balancing these upgrades can lead to improved performance, but it's essential to note that over-upgrading can also lead to diminishing returns. Finding the right changes can be a trial-and-error process.

Related Posts

-

10 Essential Tips for Understanding Aircraft Systems Effectively

-

2026 How to Optimize Consolidated Fuel Usage for Energy Efficiency?

-

2026 Best Aircraft Service Options for Travelers and Airlines

-

Innovative Aviation Kits Showcase Opportunities at the 2025 China Import and Export Fair

-

Top Precision Aircraft Innovations to Watch in 2025 for Aviation Enthusiasts

-

What is Fuel System Aviation and How Does It Impact Flight Safety