How to Optimize Fuel Injection System for Aircraft Performance

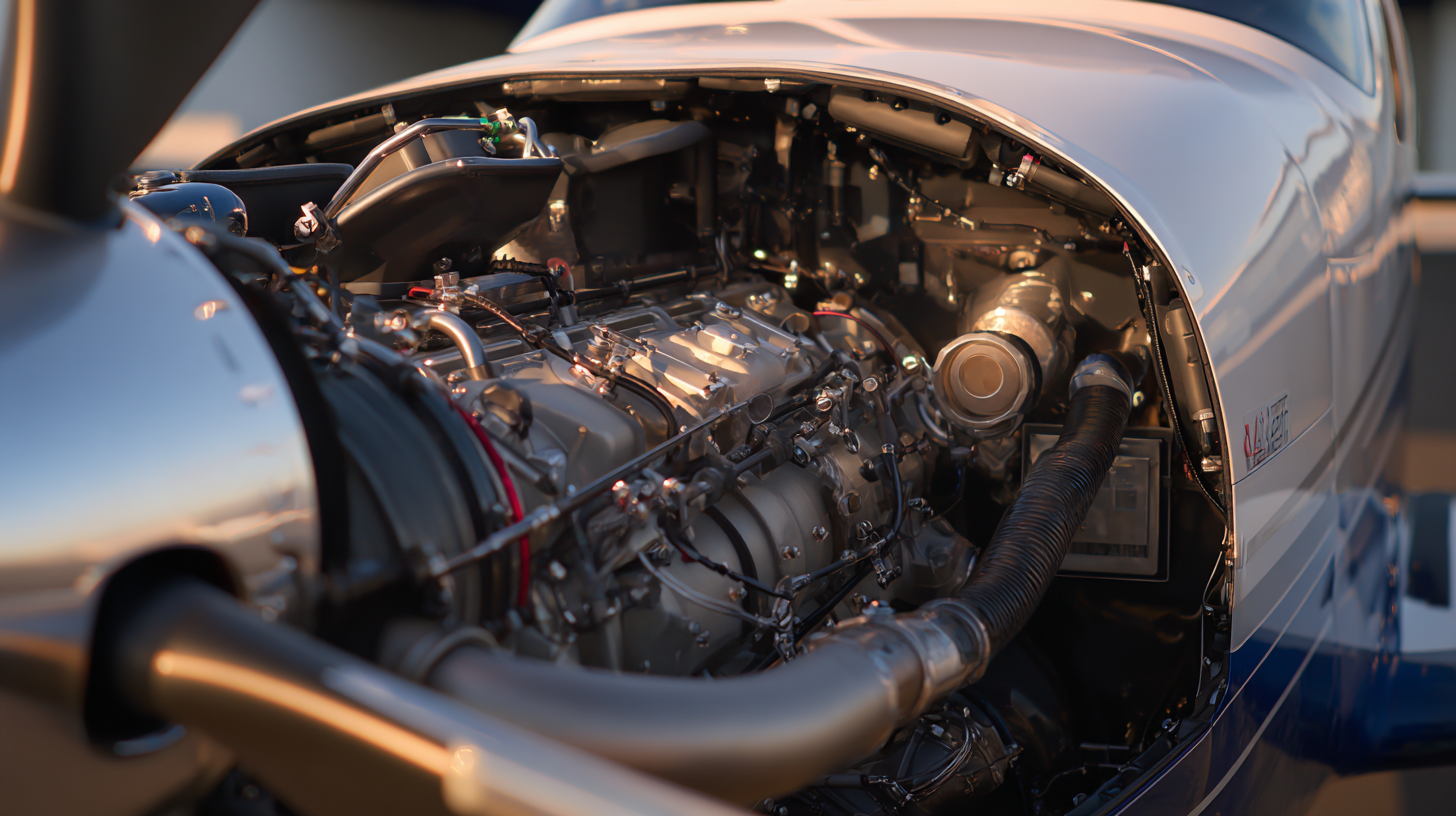

The optimization of the fuel injection system in aircraft is a critical factor that enhances overall performance and efficiency. According to the Aerospace Industries Association, advancements in fuel injection technology can improve engine efficiency by up to 25%, significantly reducing operational costs and environmental impact. As the aviation sector continues to face increased pressures to comply with stringent emissions regulations, optimizing fuel injection systems becomes not just a preference, but a necessity for sustainable growth in the industry.

Renowned aerospace engineer Dr. Sarah Henderson emphasizes the significance of innovation in fuel systems: "The fuel injection system in aircraft is the heart of engine performance; optimizing it is essential for maximizing thrust while minimizing fuel consumption." Her insights resonate with findings from the International Council on Clean Transportation, which indicates that modern fuel injection systems can lead to a reduction in greenhouse gas emissions by approximately 20%. This underscores the importance of focusing on fuel injection system advancements to meet both performance and regulatory requirements. With the expectation that global air traffic will increase by 4.2% annually over the next decade, the development and enhancement of efficient fuel injection techniques is paramount for the future of aviation.

Best Practices for Maintaining Fuel Injection Systems in Aircraft

Maintaining the fuel injection system in aircraft is crucial for optimizing performance and ensuring safety. According to a report by the International Journal of Aerospace Engineering, regular inspections and maintenance can enhance the system's efficiency by up to 20%. One best practice is adhering to the manufacturer's recommended maintenance schedule, which typically includes checking for fuel leaks, inspecting filters, and verifying the calibration of injectors. Neglecting these tasks can lead to reduced fuel efficiency and, ultimately, higher operational costs.

Another important aspect is the use of high-quality fuel that meets aviation standards. The American Society for Testing and Materials (ASTM) emphasizes that fuels contaminated with water or particulates can severely impede the performance of the fuel injection system. Ensuring a clean and stable fuel supply helps in preventing corrosion and blockages in the injector nozzles. Additionally, utilizing advanced diagnostic tools can identify potential issues before they escalate, allowing for proactive measures that keep the fuel injection system functioning optimally. By implementing these practices, aircraft operators can ensure maximum performance and reliability from their fuel injection systems.

Understanding the Components of Aircraft Fuel Injection Systems

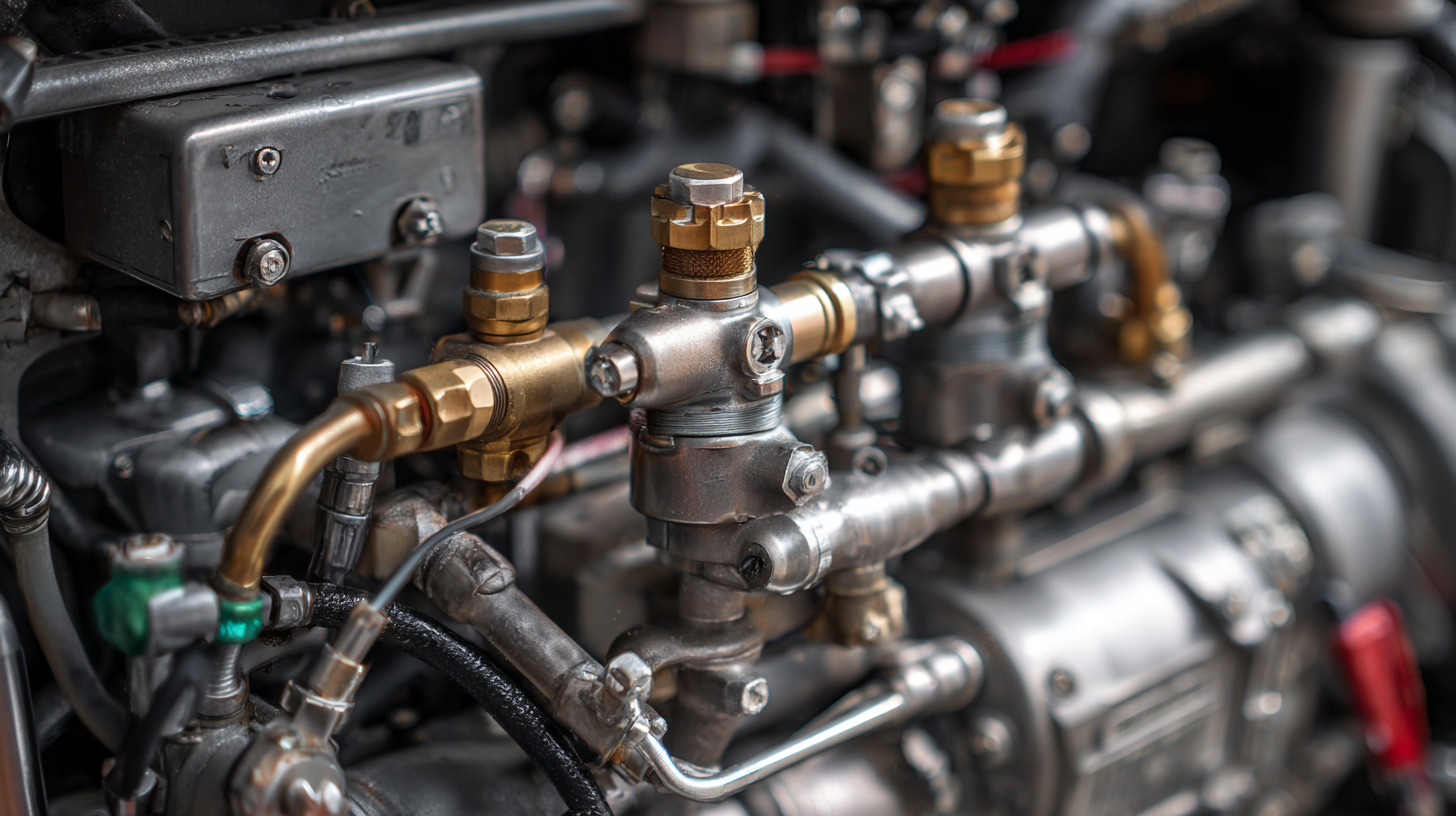

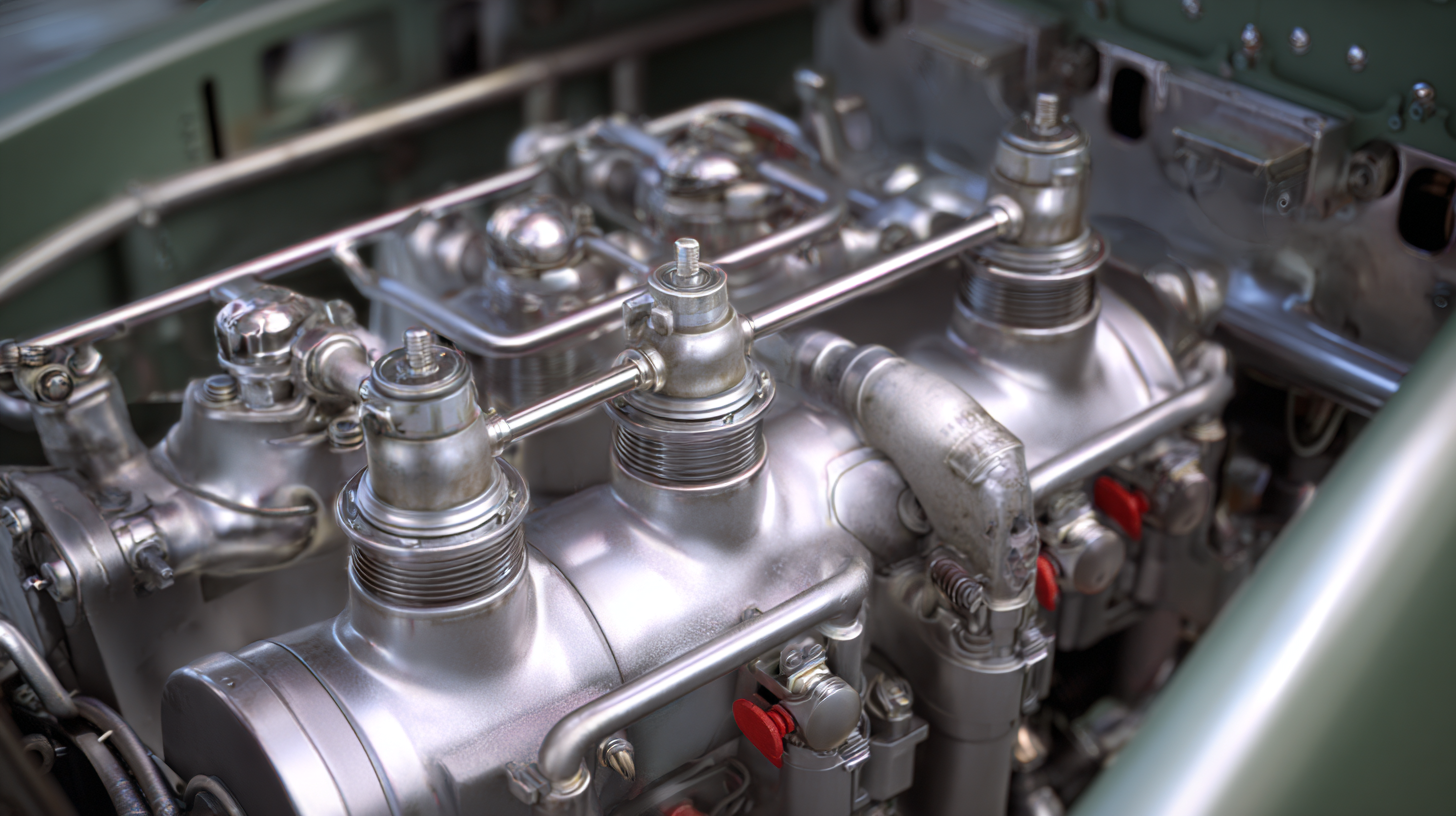

Understanding the components of aircraft fuel injection systems is crucial for optimizing performance and ensuring reliability. Aircraft fuel injection systems typically consist of several key components, including fuel pumps, fuel injectors, pressure regulators, and filters. Each of these components plays a vital role in delivering the correct amount of fuel efficiently to the engine. For instance, modern fuel injectors can operate with precision, atomizing fuel for optimal combustion, which is essential for maximizing performance and fuel efficiency.

According to a report from the International Society of Aircraft Performance Engineers, optimizing the fuel injection system can improve fuel efficiency by up to 15%. Regular maintenance and calibration of injectors can help maintain this efficiency. Additionally, using advanced materials in fuel injectors can resist corrosion and improve durability, which is essential in an aircraft's harsh operating environment.

Tips for ensuring optimal operation include regularly checking fuel pressure and flow rates, as well as performing periodic inspections of fuel filters to prevent clogging. Furthermore, investing in high-quality fuel can significantly enhance engine performance and longevity, ensuring optimal operation under various flying conditions. Always refer to the aircraft's maintenance manual for specific guidelines and manufacturer recommendations to keep the fuel injection system functioning optimally.

Key Performance Metrics for Evaluating Fuel Injection Efficiency

Optimizing the fuel injection system in aircraft is crucial for enhancing overall performance and efficiency. Key performance metrics for evaluating fuel injection efficiency include fuel flow rate, injector response time, and atomization quality. According to a recent report by the International Society of Automation, improvements in injector atomization can yield up to a 5% increase in engine efficiency, significantly impacting fuel consumption and emissions.

Optimizing the fuel injection system in aircraft is crucial for enhancing overall performance and efficiency. Key performance metrics for evaluating fuel injection efficiency include fuel flow rate, injector response time, and atomization quality. According to a recent report by the International Society of Automation, improvements in injector atomization can yield up to a 5% increase in engine efficiency, significantly impacting fuel consumption and emissions.

Another vital metric is the injector response time, which directly affects engine throttle response and overall aircraft agility. Studies indicate that reducing the response time by even a few milliseconds can enhance performance, resulting in faster acceleration and improved climb rates. A report from the Aerospace Industries Association highlights that modern fuel injection systems with optimized response times can achieve a 10% improvement in specific fuel consumption, translating to both cost savings and a reduced environmental footprint.

Additionally, monitoring the fuel flow rate is essential for maintaining optimal performance. The Aircraft Owners and Pilots Association notes that inconsistencies in fuel delivery can lead to inefficient combustion and a decrease in power output. Advanced diagnostic tools enable real-time monitoring of fuel flow, allowing for quick adjustments that ensure the engine operates within its optimal parameters, thereby maximizing aircraft performance and reliability.

Common Issues in Aircraft Fuel Injection and Their Solutions

Aircraft fuel injection systems play a crucial role in optimizing engine performance, but various issues can hinder their efficiency. One common problem is fuel contamination, which can lead to clogged injectors. To address this issue, it’s vital to implement regular fuel quality checks and maintain clean fuel storage. Using fuel filters can also mitigate contamination, ensuring that only clean fuel reaches the injectors.

Another frequent issue is improper fuel delivery, which can stem from a malfunctioning pump or faulty injectors. This can result in engine misfires or reduced power output. Diagnosing the root cause—be it a mechanical failure or wear—and replacing or servicing the defective components is essential for restoring optimal performance. Furthermore, adjusting the fuel pressure according to manufacturer specifications can help maintain consistent fuel flow and enhance overall engine efficiency. Regular maintenance and attention to these common issues can significantly improve the performance of aircraft fuel injection systems.

Techniques for Fine-Tuning Fuel Delivery for Maximum Performance

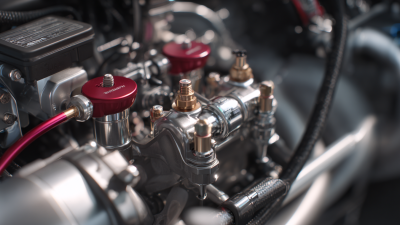

Fine-tuning the fuel delivery system is essential for optimizing aircraft performance. Understanding the balance between fuel flow, air intake, and engine demand can drastically improve efficiency and power output. One crucial technique involves calibrating the fuel injectors to ensure they are delivering the correct amount of fuel at various engine speeds and conditions. This requires precise measurements and adjustments, typically conducted through engine testing and computer simulations to analyze performance at different altitudes and speeds.

Tips: Regular maintenance checks on fuel injectors can prevent clogging, which affects fuel spray patterns and efficiency. Additionally, monitoring the fuel pressure in the system can help identify issues before they lead to significant performance losses.

Another technique is to adjust the fuel mapping based on the specific operating environment of the aircraft. Fuel mapping allows for more effective combustion by altering the fuel-to-air ratio according to the anticipated conditions. This involves programming the engine control unit (ECU) with data from previous flights and environmental variables, leading to optimized performance across diverse operational scenarios.

Tips: Pilots should log information on flight conditions and fuel consumption, as this data can provide valuable insights for future calibrations and adjustments. Collaborating with engineers to review these logs can enhance the aircraft’s fuel management strategy.

Related Posts

-

Fuel Injection Aircraft Innovations Showcased at the 138th Canton Fair 2025

-

Revolutionizing Aviation: The Future of Fuel Injection Systems in Aircraft Design

-

Exploring the Future of Fuel System Aviation at the 138th Canton Fair 2025

-

Exploring the Future of Fuel System Aviation Innovations and Sustainability

-

Unlocking the Future of Energy: How Consolidated Fuel is Revolutionizing the Fuel Industry

-

Understanding the Future of Aviation Fuel Innovations and Their Impact on Air Travel